Fish farms provide more than half of the fish on the market. And feed costs amount to around 90% of the cost of raising them.

While in some ways fish farming operations are more ecologically sustainable than wild harvest, they have their own problems. Pollution, escape of invasive species, and use of water resources plague the industry.

The origins of the food used to raise food fish — as well as other seafood like shellfish — to maturity have raised concerns as well. A large proportion of fish feed is derived either from terrestrial agriculture or from forage fish harvested from the wild that people might otherwise eat directly.

These factors have led fish farmers to pursue other options for sustaining their charges. Among the most promising are products derived from microalgae. These single-celled organisms, if processed correctly, can offer equivalent or superior nutritional profiles to grain and fish derived feeds.

While challenges remain — extracting useful feed from these organisms is expensive and requires time-consuming, difficult processes — these easily-cultivated creatures offer the promise of a more sustainable fish farming industry. And using microalgae feeds may actually improve the nutritional profile of farmed fish.

Problems with current fish feeds

Most of the fish feed currently used is derived from either wild fish or from terrestrial agricultural products. Both of these sources present problems in sourcing.

Wild fish are unreliable sources due to natural fluctuations in population and overfishing. Additionally, wild fish, even small species, are potential human food sources. Using them to feed captive fish constitutes a conflict of resource usage.

Terrestrial agricultural products present problems as well. Derived from a wide range of grains and animal byproducts, some may provide appropriate nutritional profiles. But others are not easily digested, resulting in lower growth rates and wasted feed. Some also lack essential amino acids, which may result in less nutritious flesh.

Further, terrestrial plants do not offer optimal photosynthetic conversion of energy. That is: they are not as efficient as microalgae in converting sunlight into usable products.

What are microalgae and what do they offer?

Microalgae are a group of microorganisms constituting some 50,000 known species. They are single-celled but some live in colonies. Aquatic species have shown the most promise for production of fish feed.

A number of species have already been exploited for human food, cosmetic, and energy applications. Some of the byproducts of these industries were the basis for early experiments in the use of microalgae as fish feed.

Live microalgae have been used to feed hatchling fish but larger scale use of these organisms entails processing and the extraction of the nutrients they contain in purified form. The nutritional value of microalgae can be significant. Depending on the species, they may contain high proportions of lipids, carbohydrates, or proteins.

“Microalgae biosynthesise a broad spectrum of metabolites, some of them only found in some microalgal taxa, which can be used for different applications,” says Margarida Costa, research manager of the microalgae section at the Norwegian Institute for Water Research. “Protein content, for example, can go up to 70% in the case of spirulina (Arthrospira platensis). This species contains a balanced profile of essential amino acids that is suitable for animal consumption. Other biomolecules such as carbohydrates, lipids, and pigments, which also have important nutritional properties, are often produced by the microalgal cellular metabolism under optimal growth conditions.”

Augmenting standard feed protocols with microalgae derivatives has shown great promise. They have been shown to encourage weight gain, provide antioxidant properties, and impart colouration that improves shelf appeal. They may also be more easily digestible than traditional feeds — microalgae lack lignin and hemicellulose, common in terrestrial plants. Some varieties provide prebiotic and probiotic substances. And microalgae derivatives may even improve immune health.

“Natural bioactive metabolites isolated from microalgae have been found to display antiviral, antibacterial, antimalarial, and anti-inflammatory activities,” Costa adds. “When applied to the aquafeed industry, these molecules can result in an array of new, innovative, and functional products with increased commercial value.”

Sustainable cultivation

Microalgae have additional appeal as a food source for farmed fish due to their flexible water requirements. Many species can be cultivated in wastewater or in seawater, reducing the impact on potable water supplies for human use.

In open systems, evaporation remains a significant concern. This is particularly true of saline systems; if water evaporates, it must be replaced to maintain optimum balance of suspended salts and water. Species that are highly tolerant of increases in salinity may mitigate such problems.

“They are moresusceptible to contamination, making them challenging to maintain,” Costa says of open systems. “However, there are also several algae that can growin the absence of light using organic molecules, such as acetate or glucose, as both a carbon and an energy source.”

Regardless of the method, growth media can often be recycled after microalgae are harvested. “After biomass harvesting, the reuse of the growth medium contributes to the reduction of the water footprint and the total use of the remaining nutrients in the water, contributing to the economic sustainability of the production,” Costa claims.

Efficiencies of up to 90% have been reached in some systems. Waste products from slaughterhouses and industrial agriculture processing facilities may also provide nutrients for algae that might otherwise be environmental contaminants. The REALM project is investigating ways to use agricultural effluents, including fertilizer runoff, to nurture microalgae for harvest. The microalgae may either be fed to zooplankton, which can then be used as fish feed, or fed to fish directly.

Using waste products to support microalgae production — as opposed to using microalgae simply as a mitigation strategy — will require the selection of specific strains that are able to use the nutrient content of each type of waste in a productive manner. As Costa observes, we have a long way to go until microalgae reach the optimums of production that we now demand of crop plants for human consumption.

How are nutrients extracted from microalgae?

While some microalgae are fed directly, most require processing so that fish can access the nutrients within.

Typically, the cells must be dried and then cracked to release their contents. After sun drying or air drying, the microalgae may be autoclaved, subject to various types of pressure, freeze-dried, milled, or soaked in enzyme solutions. These processes may be expensive and they are particular to the type of microalgae and thus difficult to scale.

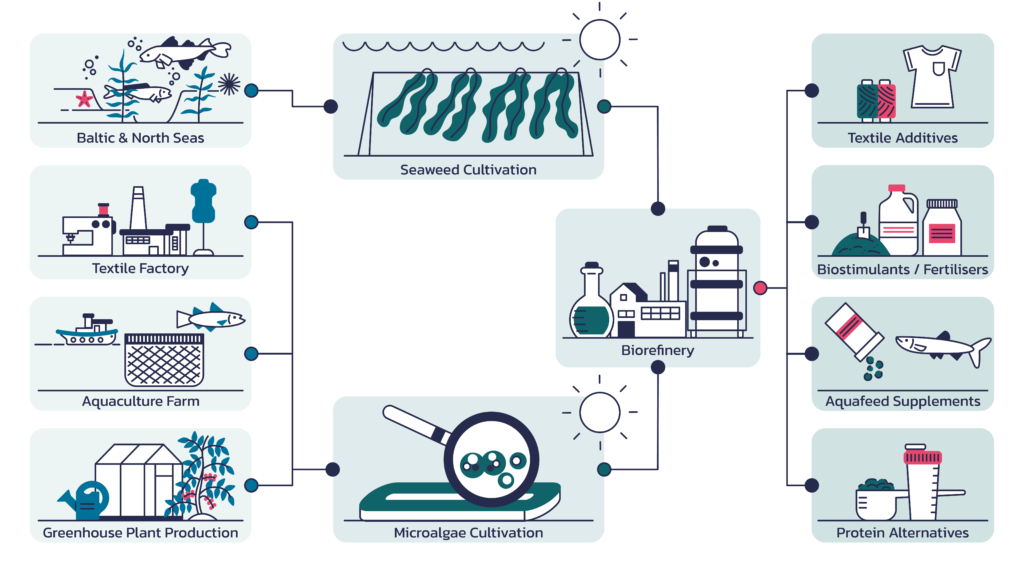

Projects such as the EU-funded research project LOCALITY are investigating best practices for turning microalgae into sustainable feed and other products.These processes, when targeted to the extraction of particular nutrients and the needs of different species of fish, can offer major benefits. Efforts to improve digestibility of the resulting feed are ongoing.Even as more refined algae-based feeds come to market, a number of concerns remain. Some species are difficult to harvest, requiring specific flocculation techniques that use toxic compounds such as aluminum. Microalgae may also accumulate heavy metals on their own — which are then passed on to the fish and ultimately the consumer. And pesticides may be required to suppress invasion of algae colonies by fungi and other undesirable organisms.

These challenges appear to be well-worth addressing giving the benefits of a wide-reaching algae cultivation industry. “Although the European algae sector is booming, the industry is still in its infancy due to high production costs,” Costa says. Scaling algae production will require further research and development—and forward-thinkingcompanies are doing just that.

This article was published in

- EARTH.ORG on 09 October 2023

The author of this article is Richard Pallardy. He is a freelance science writer based in Chicago. He has written for such publications as National Geographic, Science Magazine, New Scientist, and many others.